Brochures / articles

Product overview

Current product overview (pdf brochure) to download:

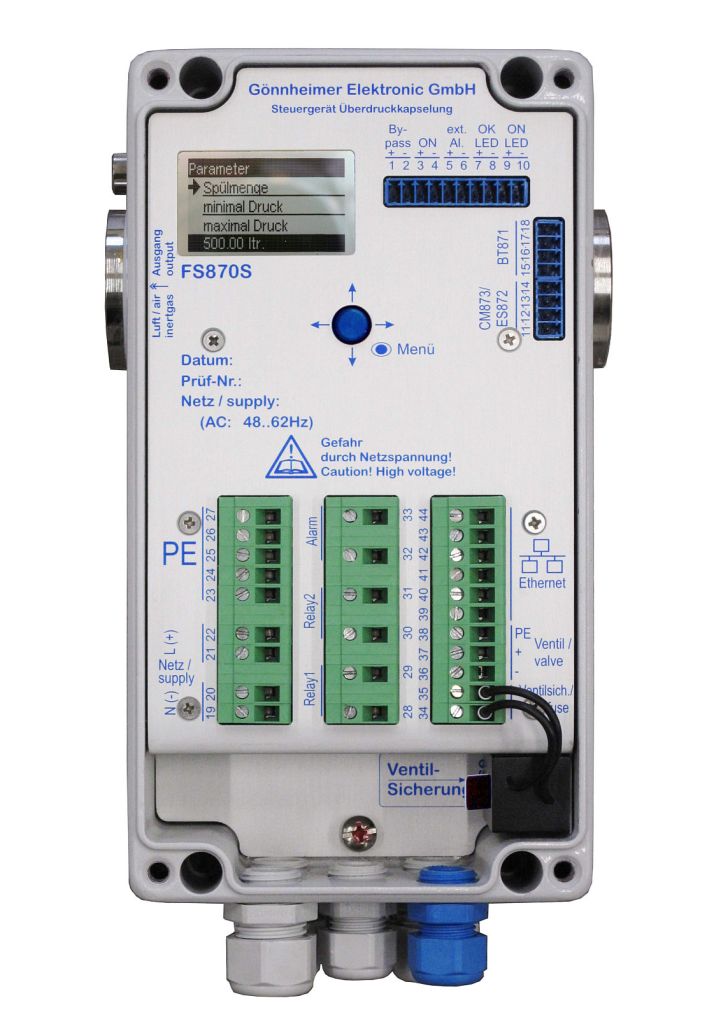

Verified non-Ex MCR components can be used in potentially explosive environments with the aid of the pressurized enclosure type of explosion protection. The pressurized enclosure is an interesting alternative, especially for small and medium quantities where the development of special Ex devices is not profitable.

In order to make non-Ex MCR components applicable for Ex areas, an Ex-free space is created within an Ex p enclosure in which the standard devices are operated.

The amount of barcode scanning required in the production environment has risen continuously in recent years due to increasing product labeling of individual components, assemblies or containers. In addition to marking the workpieces and goods produced, the identification of tools, components and assemblies in production facilities (asset management) is becoming increasingly important. Current data, inspection and service deadlines as well as calibration protocols can be called up directly in the system for the corresponding component.

Combined use of different types of explosion protection enables application-oriented use of standard PC and communication technologies in different Ex zones

The trend towards the use of standardized hardware and software platforms within modern automation systems is based on the availability of units with the highest performance at the lowest prices. This trend also brings with it unprecedented hardware and software compatibility of systems. In recent years, this has been particularly noticeable in the use of standard PC technologies in I&C systems, which are used across manufacturers and networked throughout without any additional effort.